This is a glass blog, so before I launch into

trompe l’oeil, I will say something about glass. In Readfield, Maine, there is a building called the Union Meeting House. It is on the National Register of Historic Places.

We had the good fortune of being asked to repair some of the building’s stained glass windows several years ago. This week, I was at the Union Meeting House for a David Mallett concert and got to visit our repaired windows, which are holding up great.

Windows in the Union Meeting House, Readfield, Maine.

Windows in the Union Meeting House, Readfield, Maine.

The building has some non-leaded, colored stenciled glass windows, shown above on the right side of each photo. They are very rare and are only used in one other church in Maine. As years went by, they were replaced with more traditional stained glass windows, which appear on the left in each photo.

Normally, I am “all about the glass,” but this building has something even better! This building, in this very small town, has one of the finest examples of

trompe l’oeil there is, the reason it was put on the National Register of Historic Places in 1982.

Trompe l’oeil is French for “to fool the eye.” The walls and ceilings of this building are painted plaster, which appears to be three-dimensional. There are columns (like you see in the pictures above), medallions, wall plaques and arches that look like they protrude, but they are flat. They are so realistically painted that you just can’t believe they are actually flat and really want to touch them. However, this sign sits on a sill:

A sign warns visitors not to touch the walls.

This shows more examples of

trompe l’oeil. All of this is flat!

Another example of trompe l'oeil.

One of these jobs was in 2008 when we had the privilege of restoring two windows from the First Congregational Church of Blue Hill. We were told the windows were originally made by Alfred E. Bell, a renowned stained glass artist of the 1800s. These windows were 6’ by 12’ and were exceptionally heavy because they were all plated. Each piece was at least two layers thick, and some were three layers thick. That created some interesting challenges in the restoration.

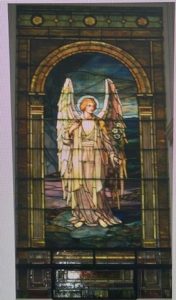

Another exciting job we did was a window called the Traveling Angel. It was from the Fairfield United Methodist in Fairfield Center, Maine. This window was made by the Belcher Glass company based in New Jersey. It was a unique process. It involved placing tiny pieces of glass on a paper pattern. When I say tiny, I mean like fingernail size! The pieces of glass and the pattern were then covered on both sides with a gummed sheet of asbestos. A frame was placed around the outside edges of the glass-filled asbestos sheets to seal the glass. Molten lead was then poured between the asbestos sheets, filling the gaps between the small pieces of glass. When the metal cooled, it bound the glass pieces together.

There were very few of these windows made because the process was toxic, and the workers died! There are approximately 30 of these windows in existence.

One of these jobs was in 2008 when we had the privilege of restoring two windows from the First Congregational Church of Blue Hill. We were told the windows were originally made by Alfred E. Bell, a renowned stained glass artist of the 1800s. These windows were 6’ by 12’ and were exceptionally heavy because they were all plated. Each piece was at least two layers thick, and some were three layers thick. That created some interesting challenges in the restoration.

Another exciting job we did was a window called the Traveling Angel. It was from the Fairfield United Methodist in Fairfield Center, Maine. This window was made by the Belcher Glass company based in New Jersey. It was a unique process. It involved placing tiny pieces of glass on a paper pattern. When I say tiny, I mean like fingernail size! The pieces of glass and the pattern were then covered on both sides with a gummed sheet of asbestos. A frame was placed around the outside edges of the glass-filled asbestos sheets to seal the glass. Molten lead was then poured between the asbestos sheets, filling the gaps between the small pieces of glass. When the metal cooled, it bound the glass pieces together.

There were very few of these windows made because the process was toxic, and the workers died! There are approximately 30 of these windows in existence.

This picture shows a glazier, Lisa Lucas, from Oakes & Parkhurst Glass helping us reinstall the window after we flattened the curve in it, fixed the painted the face and did some other repairs including rebar to strengthen it.

This picture shows a glazier, Lisa Lucas, from Oakes & Parkhurst Glass helping us reinstall the window after we flattened the curve in it, fixed the painted the face and did some other repairs including rebar to strengthen it.

For the first time we offered a class in restoration! It seems there are more pieces of glass to be restored than the time and people to do it. We hope that some of the students will continue to work on their skills and eventually start taking on restoration jobs.

The pieces they restored were likely originally installed in the old Methodist Church in Fairfield, Maine (though that building burned long ago and their provenance is not definite.) There were eight panels in various states of decay, and some of them were missing several pieces of glass. They were also each unique, despite being a "matched" set. Some had round faceted crystals in the design, and all had slight variations in glass color. It was an intensive process that took some students weeks to complete. Here you can see some of the detailed steps, the immense satisfaction of a completed project, and 3 very different final interpretations of the restored windows.

For the first time we offered a class in restoration! It seems there are more pieces of glass to be restored than the time and people to do it. We hope that some of the students will continue to work on their skills and eventually start taking on restoration jobs.

The pieces they restored were likely originally installed in the old Methodist Church in Fairfield, Maine (though that building burned long ago and their provenance is not definite.) There were eight panels in various states of decay, and some of them were missing several pieces of glass. They were also each unique, despite being a "matched" set. Some had round faceted crystals in the design, and all had slight variations in glass color. It was an intensive process that took some students weeks to complete. Here you can see some of the detailed steps, the immense satisfaction of a completed project, and 3 very different final interpretations of the restored windows.

Want to be notified when we publish a new blog post? Sign up Here

Want to be notified when we publish a new blog post? Sign up Here